Tail, Turn, Brake Add-On LED Light Kit for SEMI-TRUCKs

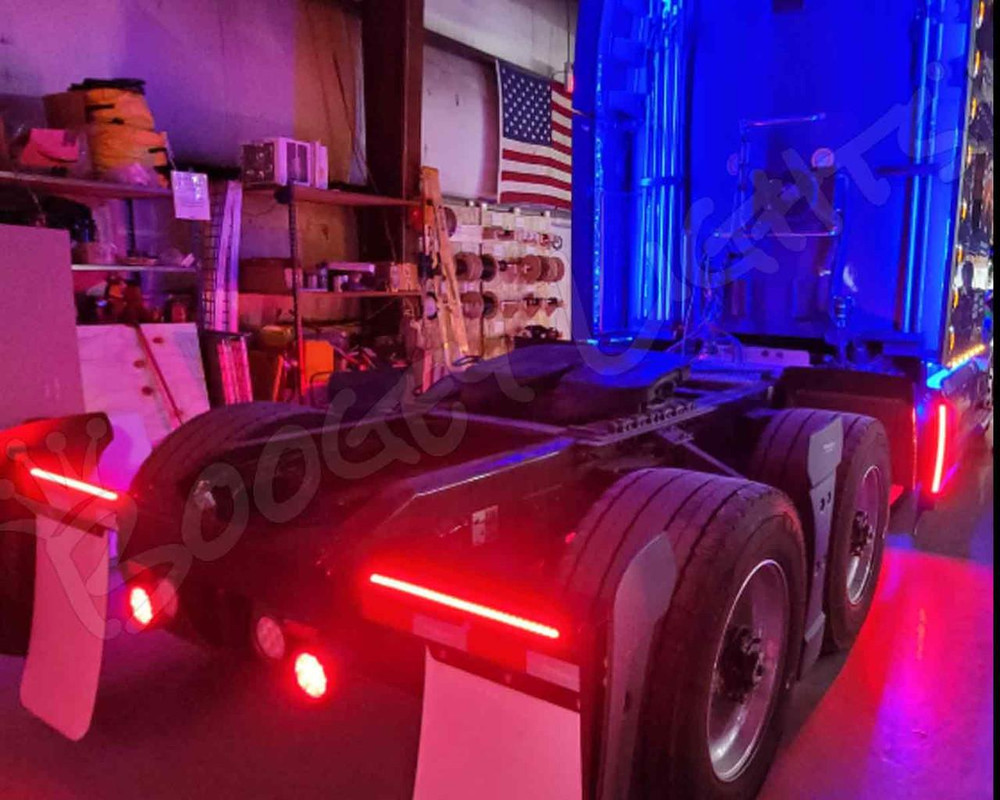

Improve the visibility of your SEMI-TRUCK's rear with Boogey Lights® TAIL - TURN - BRAKE add-on led strips.

Are the tail, turn and brake lights clearly visible to those traveling behind you when Bobtailing? Probably not. Most semi-trucks only have two small tail/turn/brake lights mounted at the rear of the truck. It's the minimum DOT required. Even when you're pulling a trailer, there are no turn signal lights that are clearly visible to drivers on either side of the truck.

Boogey Lights® TAIL - TURN - BRAKE add-on led strips are an easy and inexpensive solution to improving the visibility of your truck's rear. Built on our popular HEAVY DUTY LED Strip, they are available in both RED (3 diodes) and REDA (3 diodes red + 1 diode of amber) for those who want to wire their turn signals to the amber diodes. They're designed to mount on the leading edge of the vertical fairings on each side of the truck as shown in the product photo gallery.

This product is highly configurable to fit virtually any truck. It can be ordered with up to seven (7) pairs of LED strips to provide coverage for the vertical fairings on both sides of the truck. You do not however have to order all seven pairs of lights. The minimum is one pair. Pricing includes the led strips for BOTH SIDES OF THE TRUCK. The light kit includes the relays, relay housing and related wiring required to connect this light kit to your truck's existing brake/tail/turn lights such that it will not interfere with your trucks Lighting Control Module (LCM). This is an ADD-ON tail-turn-brake light product. It is not intended to replace your existing factory installed tail-turn-brake lights.

HEADS UP! We urge you to read the information presented here before purchasing. Our product documentation is very thorough. Product specs, an explanation of the available configuration options, 12vdc power considerations you should be aware of, wiring information, installation documentation and even a video are ALL on this product page. Chances are every question you have about this product (and more you didn't know you needed to know) are answered here. Be sure to scroll down, expand each text group section and read the information presented. Also, click on and read the information on the INSTALL INFO tab where we cover important installation considerations. Trust us when we tell you to take the time to read the information presented on this product page and in the installation documents. It's very detailed.

FAQS | Frequently Asked Questions

While we encouarge you to read all of the information presented on this product page (including the information on the navigation tabs), below are the most frequently asked questions we get about this product. In all cases, the answers to these FAQs will refer you to other sections of this product page for more details on the topic.

Will these work on my Semi-Truck?

Most likely — yes! These lights are not vehicle or brand specific. They're simple 12vdc LED strips encased in PVC rubber. You'll of course need to examine the veritcal fairings of your truck to make sure they'll fit but in our experience, it's not an issue. The RED LED strips are 5/8" wide. The REDA LED strips are 3/4" wide. They require a smooth, straight, flat, rigid / sturdy surface. This product is built on our Heavy Duty LED strips which will easily attach to most fairing edges. For this application you'll notice we offer just two strip lengths: 12" (15 LEDs) and 22" (30 LEDs). Nothing longer can be used on these vertical fairings. Why? Because these fairings move, flex and vibrate at highway speeds. Our 12" and 22" Heavy Duty LED strips do not have any seams or solder joints in them which means they'll withstand the contant vibration/flexing. The longer LED strips do have seams/solder joints in them which will fail prematurely if you mount them on the fairings. Note too this kit includes relays, a relay housing and the necessary power lead wire to connect the system to your truck's existing tail-turn-brake lights (at the rear of the truck) such that the Lighting Control Module (LCM) is completely bypassed. When installed according to the instructions, adding these lights will not impact your truck's existing lighting system. Click on the INSTALL INFO tab for more information about this. You can also download the Tail-Turn-Brake Add-On Installation Docs to review before making your purchase decision.

Are these difficult to install?

If you're not sure about any of this, we urge you to download our TAIL-TURN-BRAKE Add-On Lights installation documents first so you have an opportunity to assess whether its something you want to do or if you need assistance.

How do these lights attach to the fairing?

Can I wire in my Turn Signal to a AMBER LED instead of RED?

How To Order

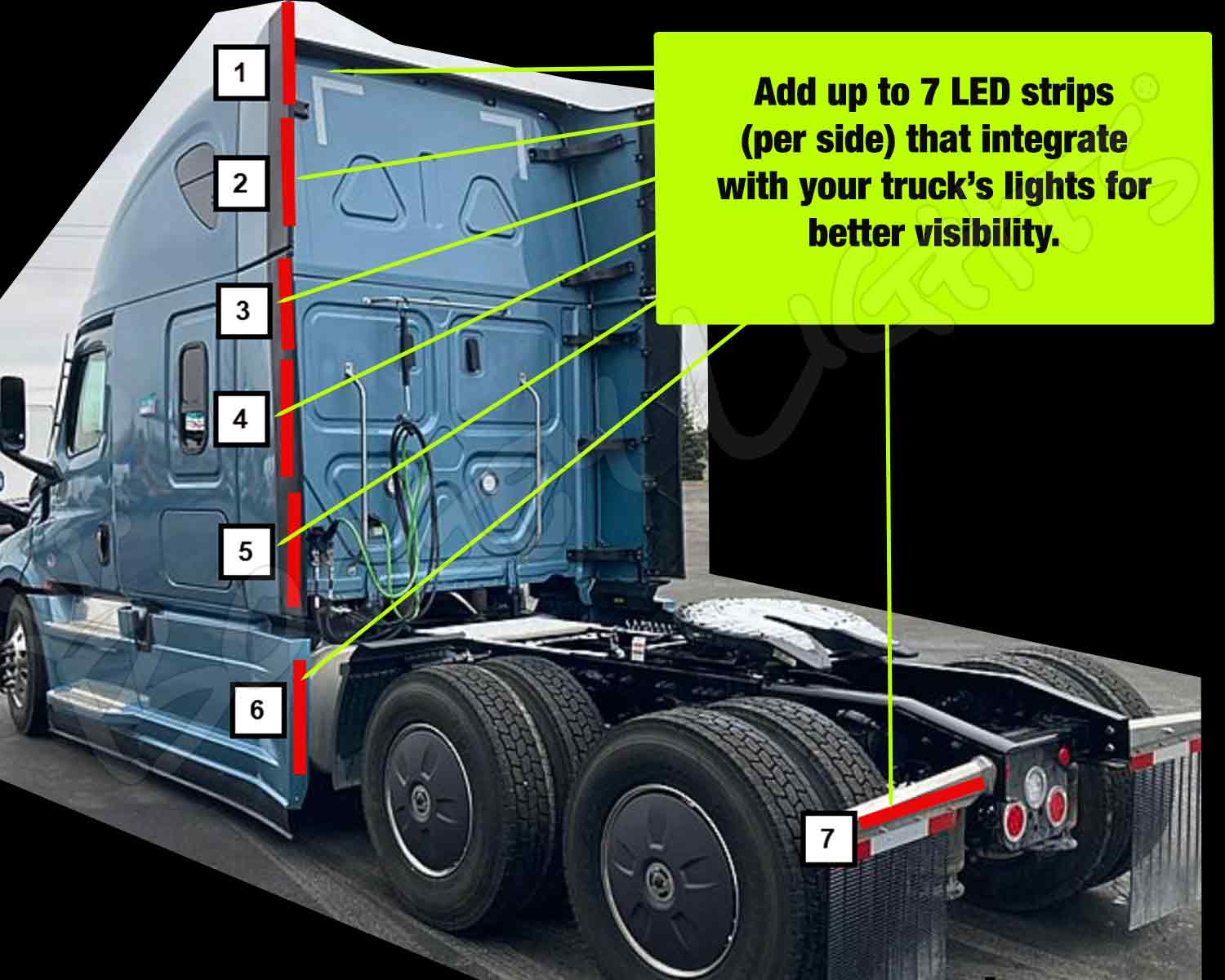

You can order up to seven pairs of LED light strips to attach to the vertical fairing of your truck. The diagram below shows the 7 possible mounting locations. The numbers of 1 to 7 in the diagram match the product option 'LED STRIP 1' to 'LED STRIP 7' on this product page. You do not have to order all 7 pairs. The minimum is one pair. For those LED strips you don't want, simply select NONE. Here are the steps to place your order:

1. First, make your LED color selection. For most people, RED (the default) is what they want. This provides three diodes of super bright RED (one diode is wired to the running lights, one diode to the brake lights and one diode to the turn signals). If you want REDA, adjust your LED color selection accordingly. If you select REDA, be sure to scroll down and read the section titled, 'WHAT IS RED + AMBER (REDA)?' as well as the installation information found on the 'INSTALL INFO' navigation tab.

2. Using the layout diagram below, determine where you want to add these Tail-Turn-Brake light LED strips to your truck. Keep in mind that the LED strip must be mounted to a smooth flat surface in a straight line. They cannot bend around corners nor can they span multiple mounting surfaces. Many trucks will have an upper and lower fairing structure. These LED strips cannot span those fairings. If you're adding an LED strip in position 7 (horizonally on the mud flap), make sure that location is smooth and flat. These LED strips cannot be mounted on top of bolt heads, screws, flanges, etc. Smooth and flat only.

3. Once you know where you want to add these LED strips, measure the amount of room you have. There are only two lengths available: 12" and 22". The 12" LED strip needs about 14" of mounting room and the 22" needs about 24" of mounting room to accomodate the end caps and the power lead wire coming out of one end. Keep in mind that these LED strips are very bright. You don't need 100% full coverage to achieve the objective of being seen.

4. Write down the lengths of the LED strips you want (12" or 22" ) for each LED Strip number 1 thru 7 on the diagram below. You do not have to use all 7 LED strip segments. Use the ones you want and set the rest to NONE.

5. Using the numbers from step 4 above, fill out the product page information to match the lengths you need. Each product option has a drop down box offering three possible selections: 12", 22" or none. That's it.

6. Click the ADD TO CART button and complete the checkout process.

Heavy Duty LED Strips | Product Features

Our HDT Tail-Turn-Brake add-on led strips are based on our popular HEAVY DUTY LED STRIPS. The exact same product; just packaged in up to seven pairs and limited only to colors applicable to tail-turn-brake light applications to make it easier for consumers. Depending upon the length, each Heavy Duty LED Strip has 15 or 30 high-intensity super-bright 5050 tri-chip RED LEDs. The REDA LEDs has an additional 2835 diode of DOT compliant Amber. No other Heavy Duty LED strip on the market today has more LEDs per foot than Boogey Lights®. This is the same lighting product we install on the bottom of Semi-Trucks, Wreckers and similar heavy duty commercial vehicles that operate in harsh environments. For this application they're offered in two lengths only: ~12" (15 LEDs) and ~22" (30 LEDs). Each Heavy Duty LED strip include a 36" power lead permanantely attached to one end of the strip. The kit includes additional wire to extend these power leads so they can be connected together on each side of the truck.

The 3 diode RED versions are .5" wide. The 4 diode REDA versions are .75" wide. All are .25" high. All include a 36" power lead. The power lead wire is 22awg. These LED strips do not have connectors on them. Just bare wire at the end so they can be used in a wide variety of applications. You can of course add your own connectors if you want but they're designed to be hard wired directly into the existing tail-turn-brake light assembly. Additionally, the end caps have a screw hole allowing these strips to be riveted/screwed to the mounting surface for additional holding power if you want. The product photo carousel on this page shows photos of the lights.

What is RED + AMBER (REDA)?

REDA is a new type of LED strip we designed. It uses our single color RED tri-chip technology with the addition of a fourth diode that is AMBER. Designed primarily for motor vehicle tail-turn-brake applications, that fourth AMBER diode can be wired to the left and right turning indicator circuits. The remaining three RED diodes are wired such that one diode connects to the running light circuit and the remaining two diodes connects to the brake circuit.

HEADS UP! Most semi-trucks DO NOT have separate turning indicator and brake light circuits mounted on the rear of the vehicle. Most are setup such that the Brake light and the Turning Indicator share the same circuit (at least on the rear of the vehicle). If you're buying the REDA version of this product thinking you'll use the Amber led for your turning indicator you will have to pull the turning indicator circuit from another location on your truck; usually from a forward location. To be clear, it's not difficult to do. Just takes more time to complete the installation as you'll need to extend the left/right turning indicator circuit wiring from another location to the relay housing to connect the Amber diodes.

Product Appearance Note

For the HEAVY DUTY LED Strips, the PVC molding and polyurethane/epoxy coating that protects the LED strip itself may have some imperfections in the material surrounding the LED strip due to the manufacturing process. It's unavoidable. We build and warranty these products for their performance in tough, outdoor environments on all kinds of heavy duty vehicles; not for their cosmetic perfection. For most applications, these LED strips are never seen as they're usually mounted to the bottom of a vehicle out of sight. You only see the glow from the LEDs and even then, only when it's dark. For this product however, because of where they are mounted you will see the LED strips themselves; especially in day light. If you're looking for a super-bright, tough, easy to install add-on TAIL/TURN/BRAKE light, this product is ideal for your application. If however you're very particular on how something looks and/or are expecting a perfectly formed hardened plastic look when viewed up-close in the light of day, the Heavy Duty (HD) product is probably not for you.

Looking for Another Color?

The TAIL-TURN-BRAKE light add on LED strips offered on this product are RED (or RED+AMBER). We however offer both the Heavy Duty LED strips and Low Profile LED strips in a variety of other colors. For example, if you're looking for White, Amber or Orange LED strips, you can find them listed with our HEAVY DUTY LED STRIPS or LOW PROFILE LED STRIPS.

Video

Here's a 30 second video of this Tail-Turn-Brake light kit in action.

DOT Compliance

The AMBER and RED single color LED strips are DOT COMPLIANT. They conform to applicable provisions of the Federal Motor Vehicle Safety Standard 108 requirements. Click on the button below for more information on this issue.

Product Appearance Note

For the HEAVY DUTY LED Strips, the PVC molding and polyurethane coating that protects the LED strip itself may have some imperfections in the material surrounding the LED strip due to the manufacturing process. It's unavoidable. We build and warranty these products for their performance in tough, outdoor environments on all kinds of heavy duty vehicles; not for their cosmetic perfection. For most applications, these LED strips are never seen as they're usually mounted to the bottom of a vehicle out of sight. You only see the glow from the LEDs and even then, only when it's dark. For this product however, because of where they are mounted you will see the LED strips themselves; especially in day light. If you're looking for a super-bright, tough, easy to install add-on TAIL/TURN/BRAKE light, this product is ideal for your application. If however you're very particular on how something looks and/or are expecting a perfectly formed hardened plastic look when viewed up-close in the light of day, this product is probably not for you.

INSTALLATION

These lights are not vehicle specific. They'll work with any 12vdc vehicle. Installing these lights is relatively simple but it does require knowledge of 12vdc power/amperage, how to wire a 12vdc circuit and how to wire a relay. If you're unclear about any of these concepts, we urge you to seek assistance from someone who has the experience and can be on-site to assist.

Installation Overview

Installation of this light kit takes 2 - 3 hours for the RED version and an additional hour or two for the REDA version. It's important to use the supplied heavy duty relays when connecting this light system to the truck's tail/turn/brake lights. DO NOT attempt to connect these lights directly to the truck's lighting system. You'll be sorry you did. Seriously. Believe us when we say this.

For integration with the truck's tail-turn-brake lights to make the system work, you need access to these circuits: the truck's tail light circuit, left turn signal, right turn signal and brake light. In most cases, the truck's brake light uses the same light as the turn signals so the brake and turn signals use the same circuits. Where you pull those circuits from is up to you HOWEVER we prefer to pull them directly from the rear tail light assembly on the rear the truck and then run that trigger wire up to the relay housing where the connections are made to the relays. We think it's easier (and cleaner) to do it this way while minimizing the possibility you might interfere with any of the truck's other electrical systems (which is always a concern in these situations). The reality however is that you can also find these wires in the wiring harness that runs on the inside of the frame rails back to the rear tail light assembly. If you’re going to be using the frame for the ground, it's super important to make sure the surface you're connecting to is bare metal; not painted. In many cases you'll have grind off the painted surface first. To power this system we connect directly to the truck's batteries under the driver's side. Do not use any other 12vdc source. Also, it's important to pull the amperage through all four batteries, not just one. Here too, you'll be sorry if you don't take our advice on this. If you don't know how to do this, ask someone to assist you with the installation. Balancing the amperage draw across all four truck batteries is important. We include an inline blade fuse holder to make the power connection along with 10awg battery cable.

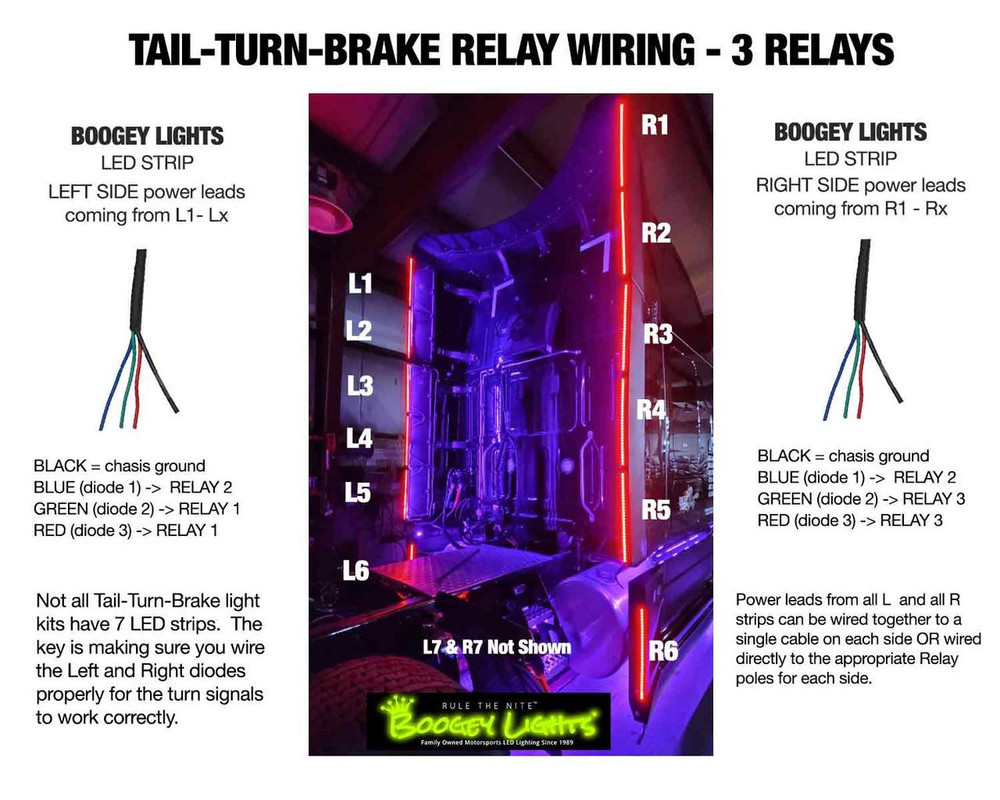

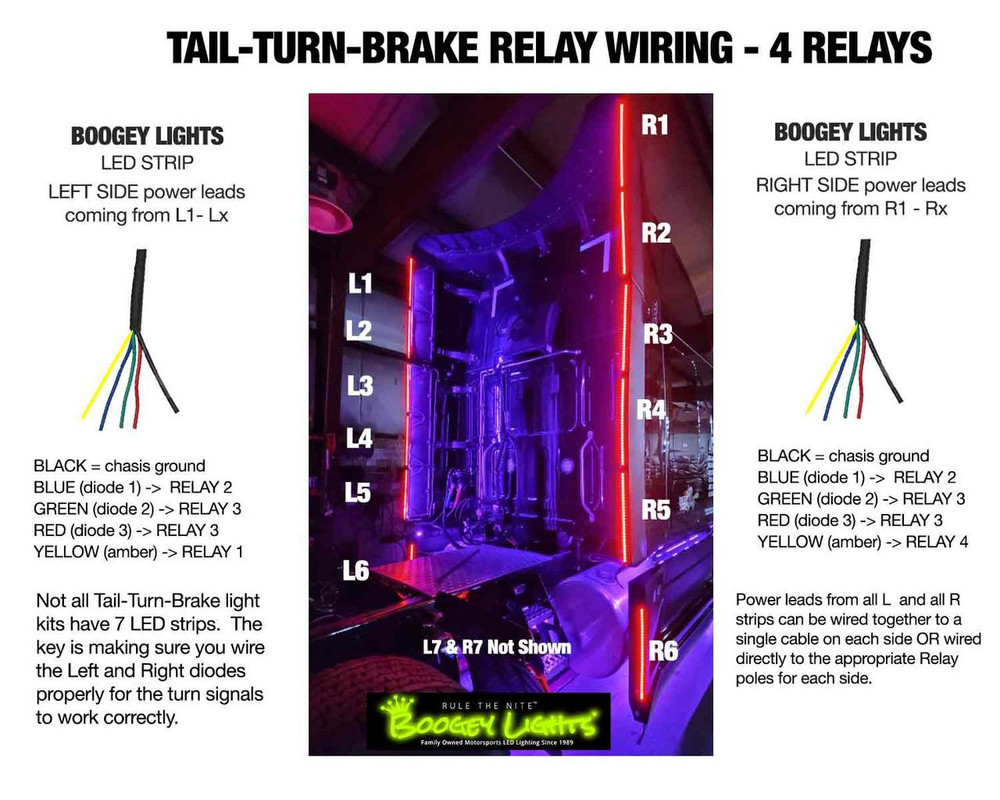

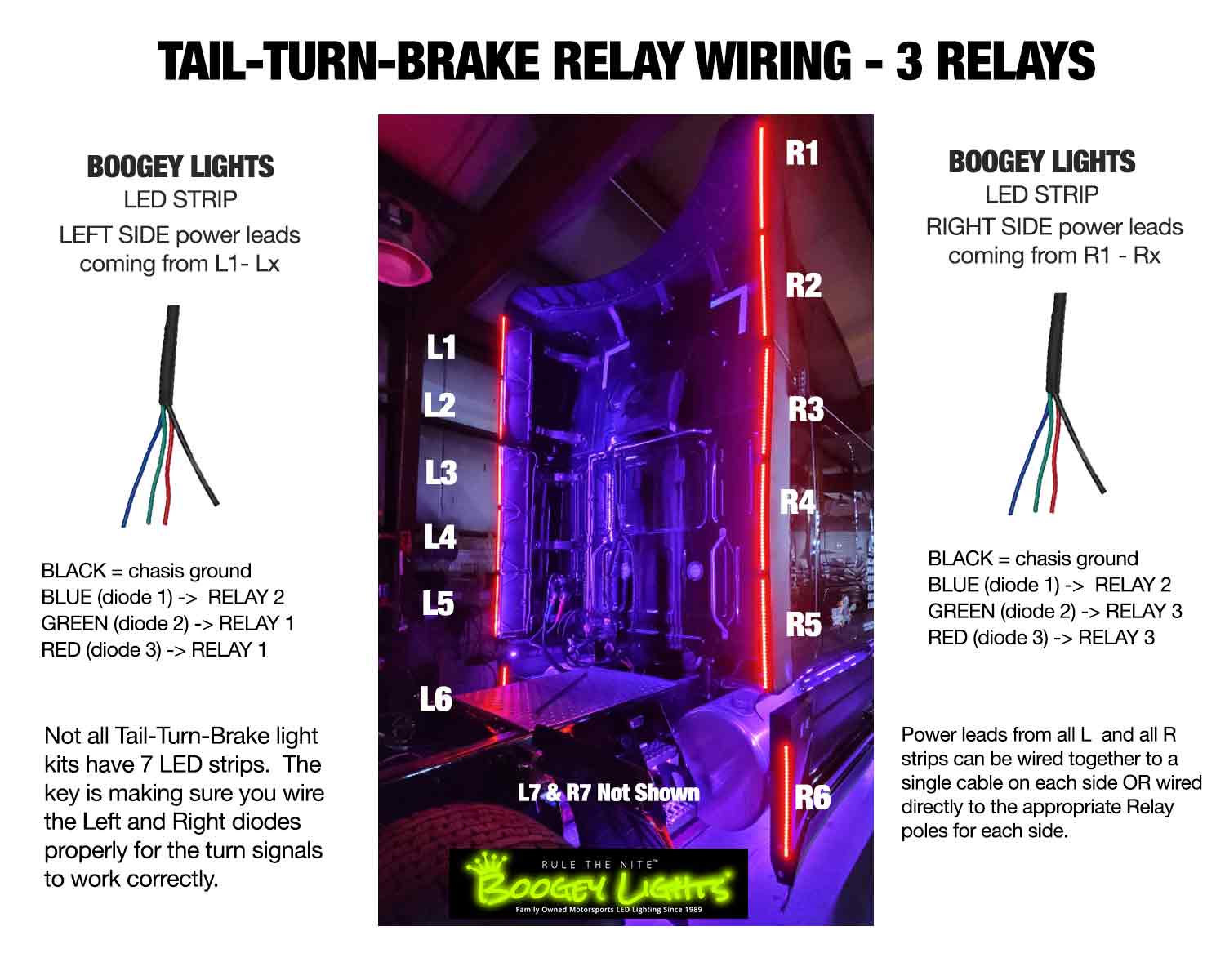

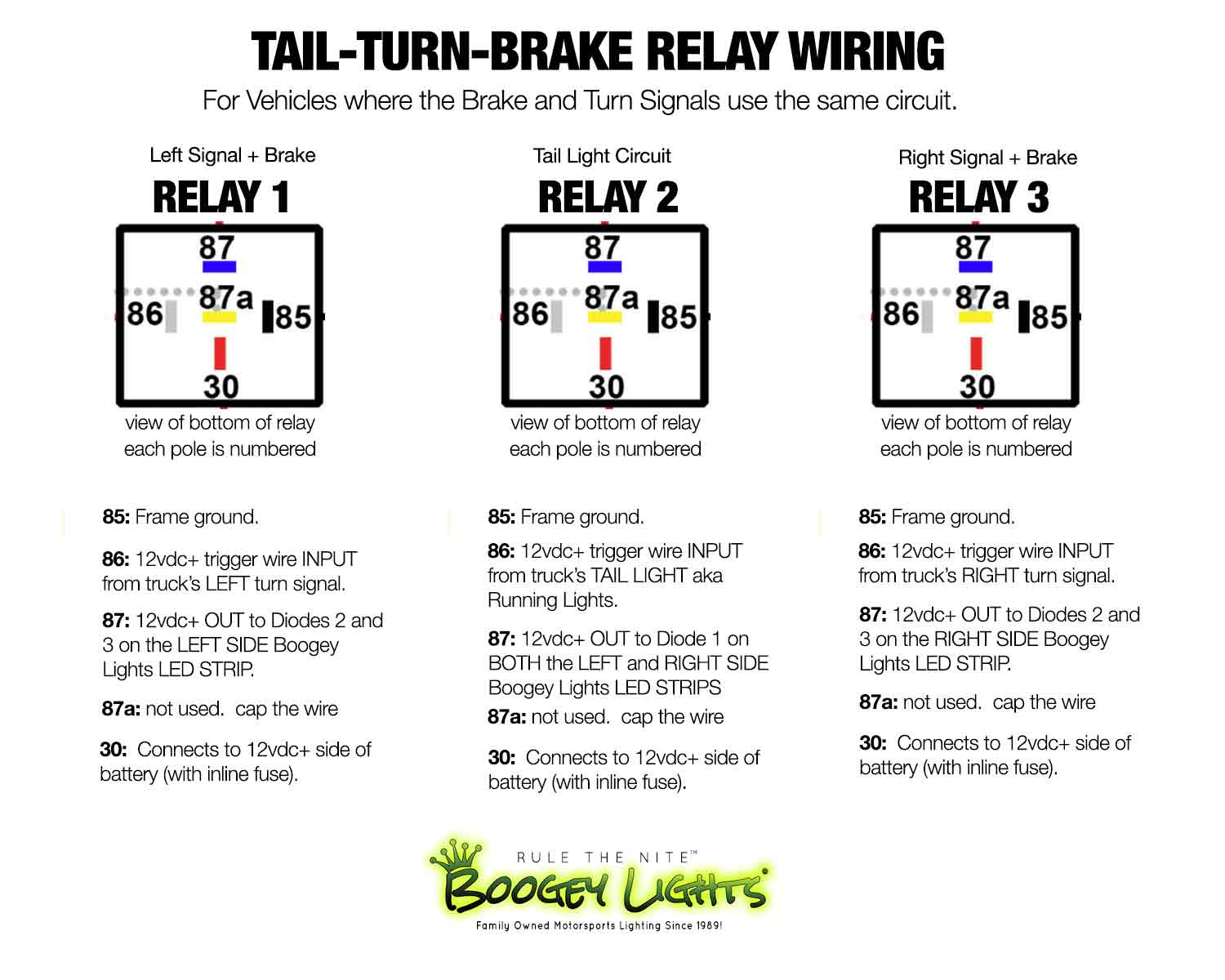

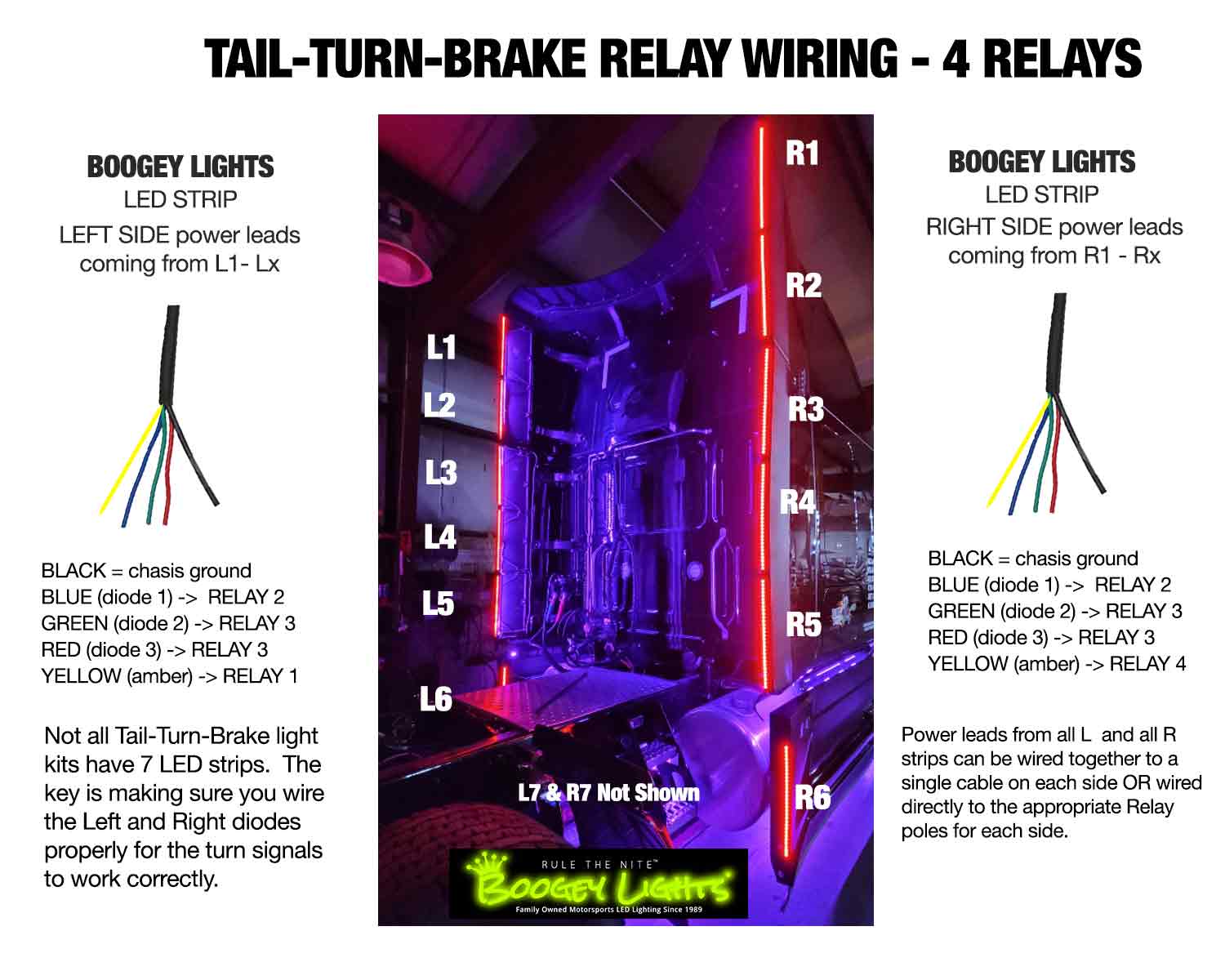

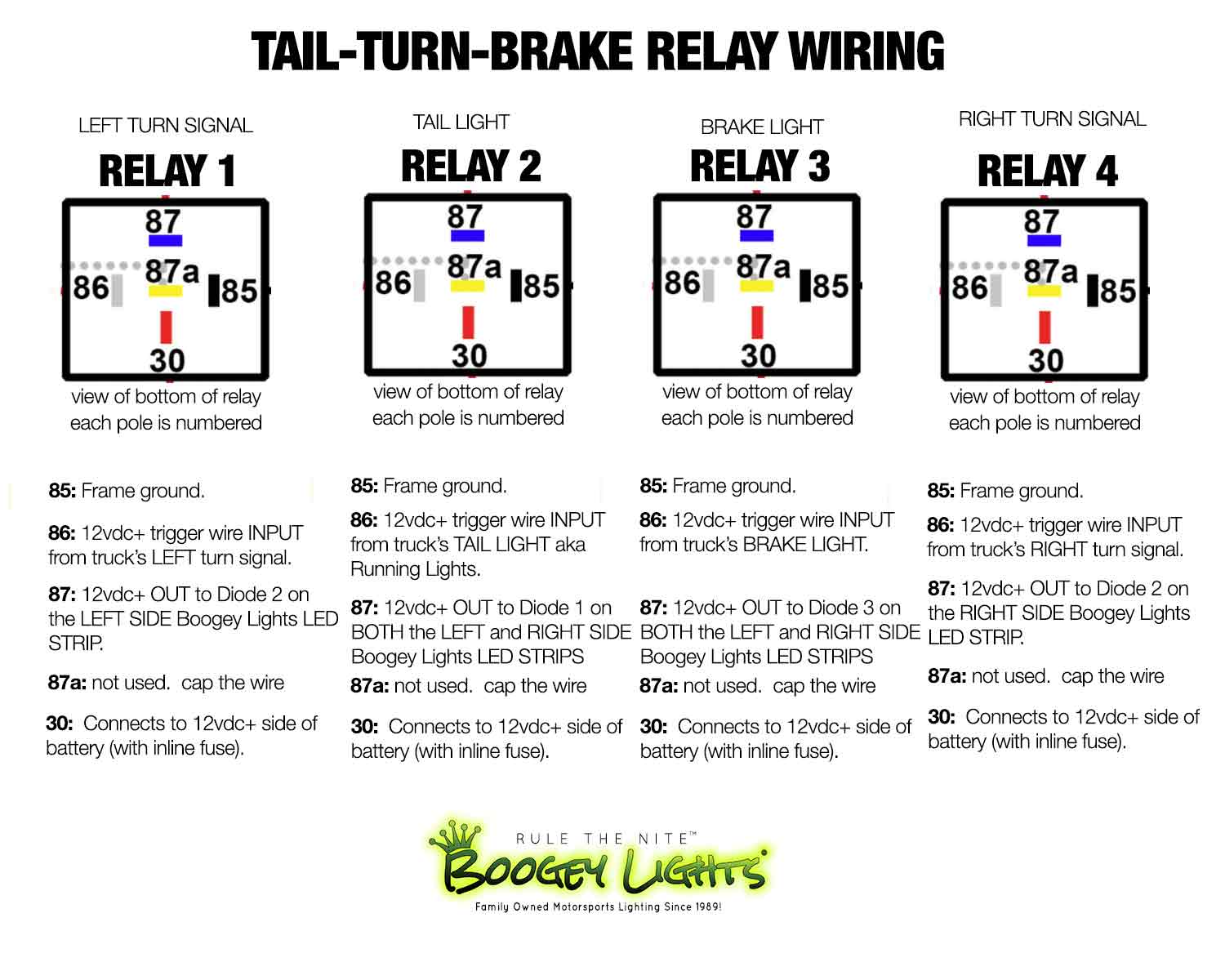

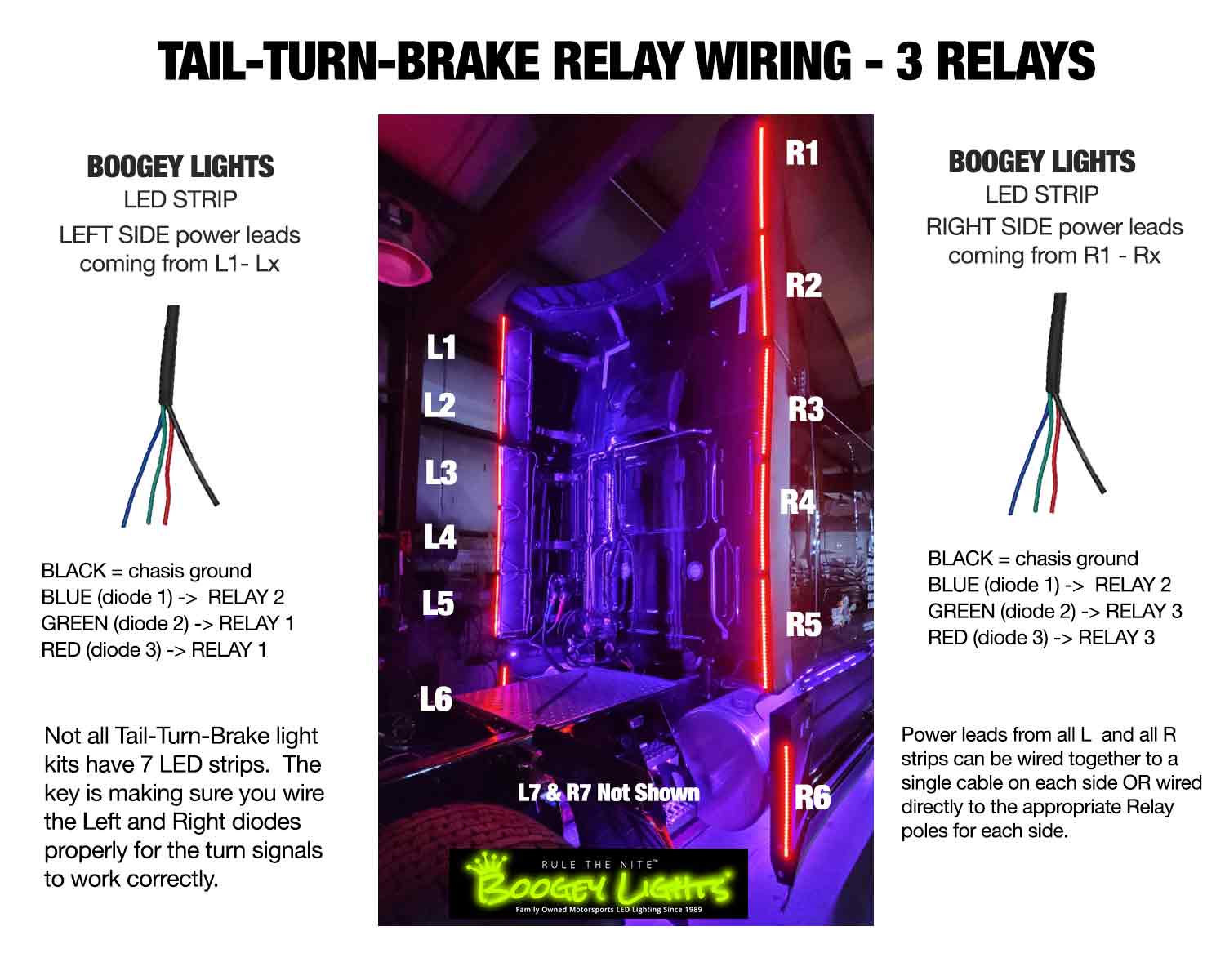

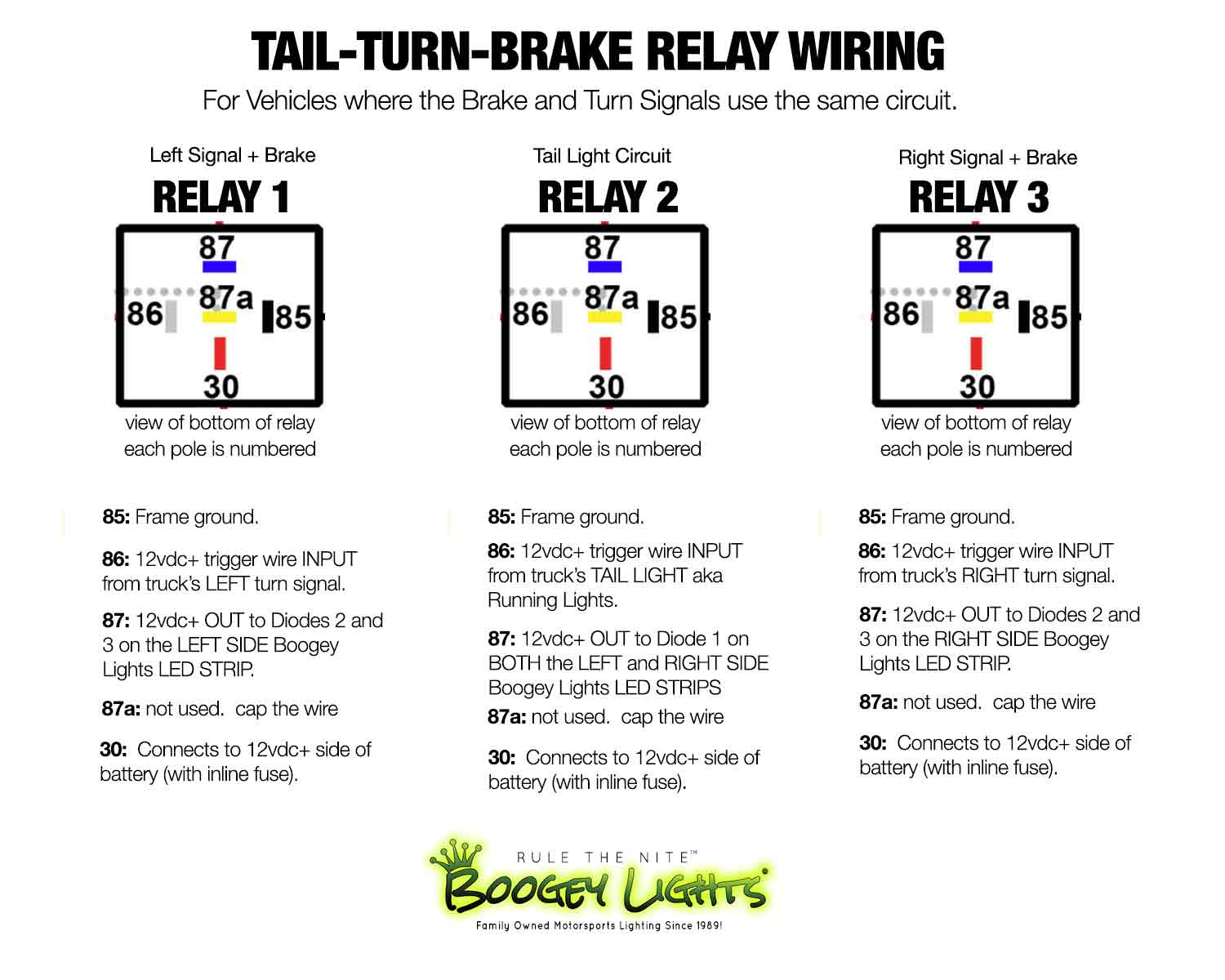

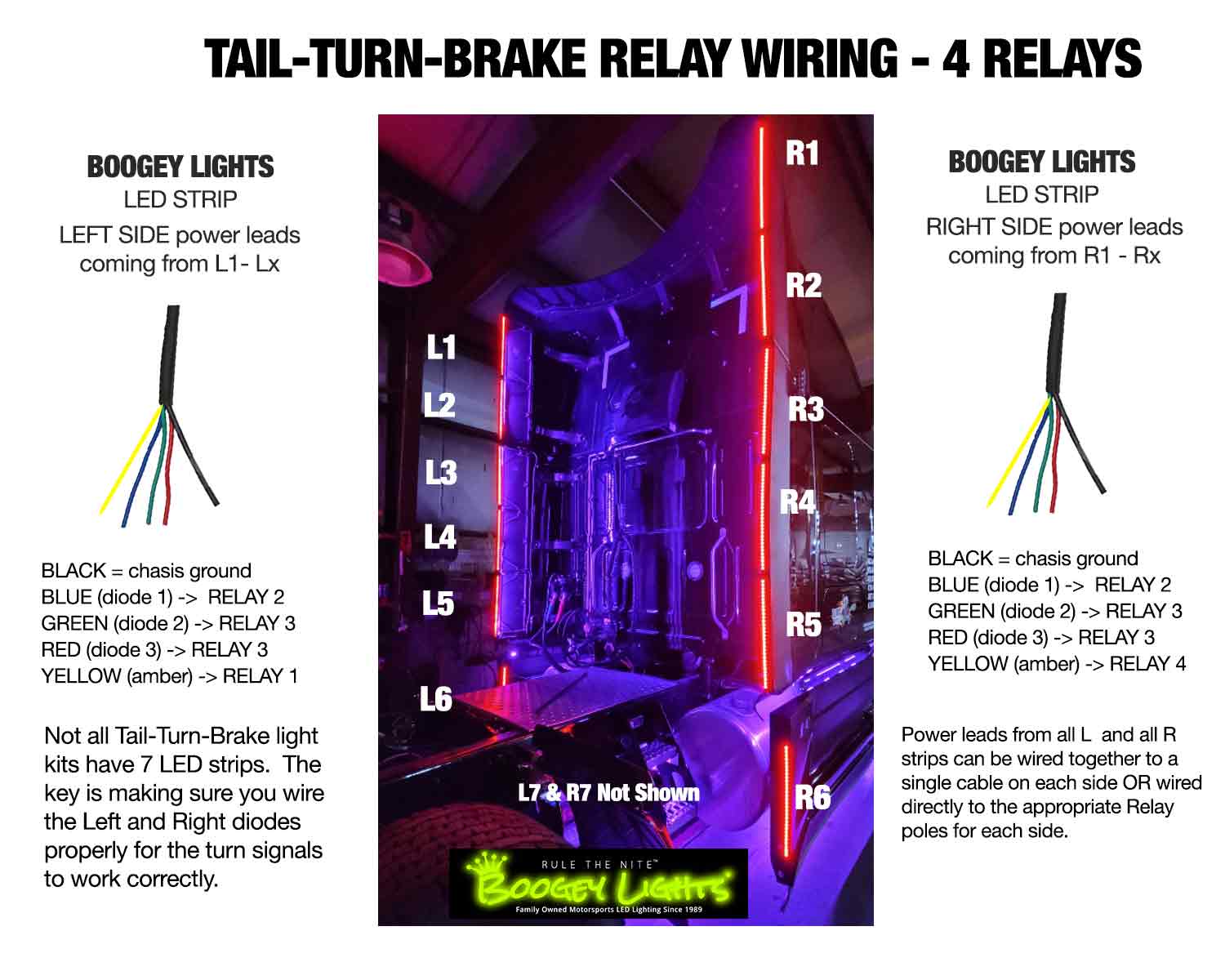

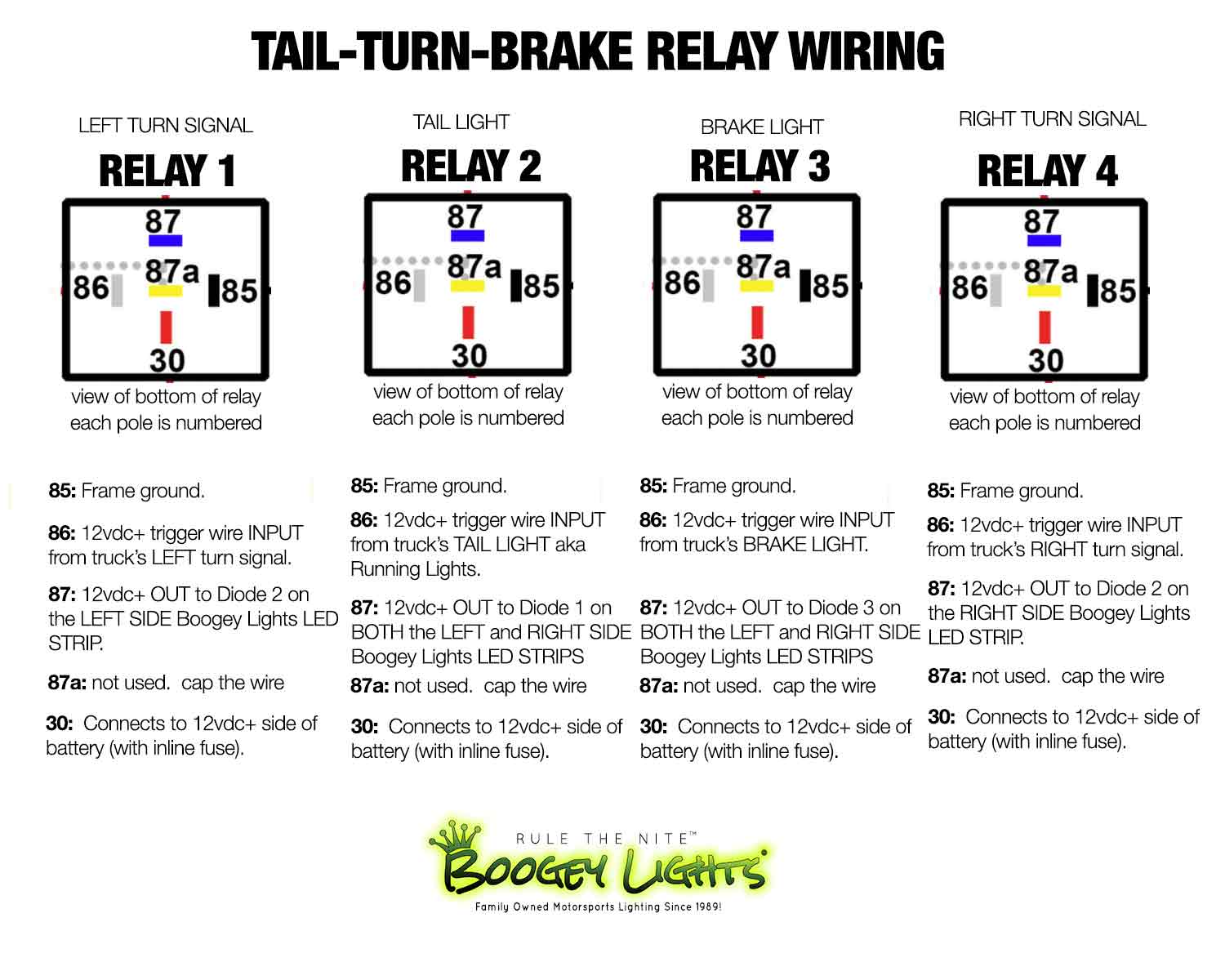

Below you'll find wiring diagrams for the RED and REDA configurations. Refer to the relay wiring diagrams for each configuration. You can also download our Tail-Turn-Brake ADD-ON LED Installation Guide before purchasing which details the entire installation process.

Layout & Wiring Overview

Wiring Diagram - RED | 3 Relays

Wiring Diagram - REDA | 4 Relays

Heavy Duty LED Strip Wiring

This light kit uses our HEAVY DUTY LED light strip. The strip has 3M VHB tape on the back of the LED strip. It require 3M Adhesion Primer to be used to secure them to the mounting surface. The power lead cable hardwired to one end of the LED strip. These HD strips are encased in black PVC rubber for additional protection with two screw holes on each end to keep the ends from moving.

Jacket Wire Colors

The black wire is always ground. All other jacket colors are 12vdc +On the Heavy Duty LED strips the wire colors will be:

- RED: Black, Red, Green, Blue

- REDA: Black, Red, Green, Blue, Yellow (yellow = Amber Diodes)

If you're unsure about which wire jacket color matches the LED diode color, it's simple enough to bench test the LED strip. You'll quickly be able to determine which jacket color matches which LED diode color. If you're not sure how to bench test, download this pdf: How to Bench Test

Wiring to Existing Tail/Turn/Brake

3 Diode RED LED STRIP: For most installations, each Boogey Lights® LED contains THREE DIODES, all of which are RED. (We offer REDA which contain FOUR diodes - 3 red and 1 Amber diode.) The number of LEDs on a LED Strip varies based on the length of the LED strip. The longer the LED strip, the more LEDs on that strip. Each LED strip has 4 conductors: One 12vdc negative (the black wire which is the ground) and then three 12vdc positive wires (color coded red, green and blue). Each of those three positive wires connects to one of the diodes in each LED. This gives you three different LED Diodes you can control making it ideal for Tail, Turn, Brake light integration. Simply wire the Boogey Lights LED strip to your existing tail light housing as follows:

- Existing Ground -> Black wire ground on Boogey Lights LED Strip

- Existing Tail Light 12vdc+ -> Red wire on Boogey Lights LED Strip

- Existing Turn Light 12vdc+ -> Green wire on Boogey Lights LED Strip

- Existing Brake Light 12vdc+ -> Blue wire on Boogey Lights LED Strip

On most semi-trucks the brake and the turn signal share the same circuit. In that case you would wire both the Green and Blue 12vdc+ wires on the Boogey Lights LED strip to the existing turn/brake light circuit on each side of the trailer. Note that some trial and error may be required to identify which wires on the existing light housing operate each of these light functions. Have a 12vdc multi-meter handy can be helpful in these cases.

4 Diode REDA LED STRIP: Each REDA Boogey Lights LED contains FOUR DIODES, three of which are RED and the fourth is AMBER. Each REDA LED strip has 5 conductors: One 12vdc negative (the black wire which is the ground) and then four 12vdc positive wires (color coded red, green, blue and yellow ). Each of those four positive wires connects to one of the diodes in each LED. This gives you four different LED Diodes you can light up.

- Existing Ground (12vdc-) -> Black wire on Boogey Lights LED Strip (12vdc -)

- Existing Tail Light 12vdc+ -> Red wire on Boogey Lights LED Strip (12vdc+)

- Existing Brake Light 12vdc+ -> Green & Blue wire on Boogey Lights LED Strip (12vdc+)

- Existing Turn Light 12vd+ -> Yellow wire on Boogey Lights LED Strip (12vdc+)

Wiring Diagram - RED | 3 Relays

Wiring Diagram - REDA | 4 Relays

3M Adhesion Primer Must be Used!

To achieve the full adhesive strength of the 3M® tape affixed to the back of the Boogey Lights® LED strips 3M® Adhesion Promoter (aka Primer) must be applied to the mounting surface first. This is an important step to ensure a secure bond. The 3M® Adhesion Promoter creates a chemical bond between the tape and the surface such that the LED strip will stay stuck (at least until you decide you want to remove it). Using any other solvent such as rubbing alcohol or acetone is not the same thing as using 3M® Adhesion Promoter. While these solvents will help clean the surface, they do not prime the surface nor can they be used instead of the 3M® Adhesion Promoter. 3M® Adhesion Promoter IS INCLUDED with this kit. If you want your strips to stay stuck it's important to follow the mounting instructions included with the kit and to use the 3M® Adhesion Promoter included.

Did we mention that using the 3M® Adhesion Promoter included in this kit is an important step in the installation process you should not skip?