Quick Shop

Quick Shop

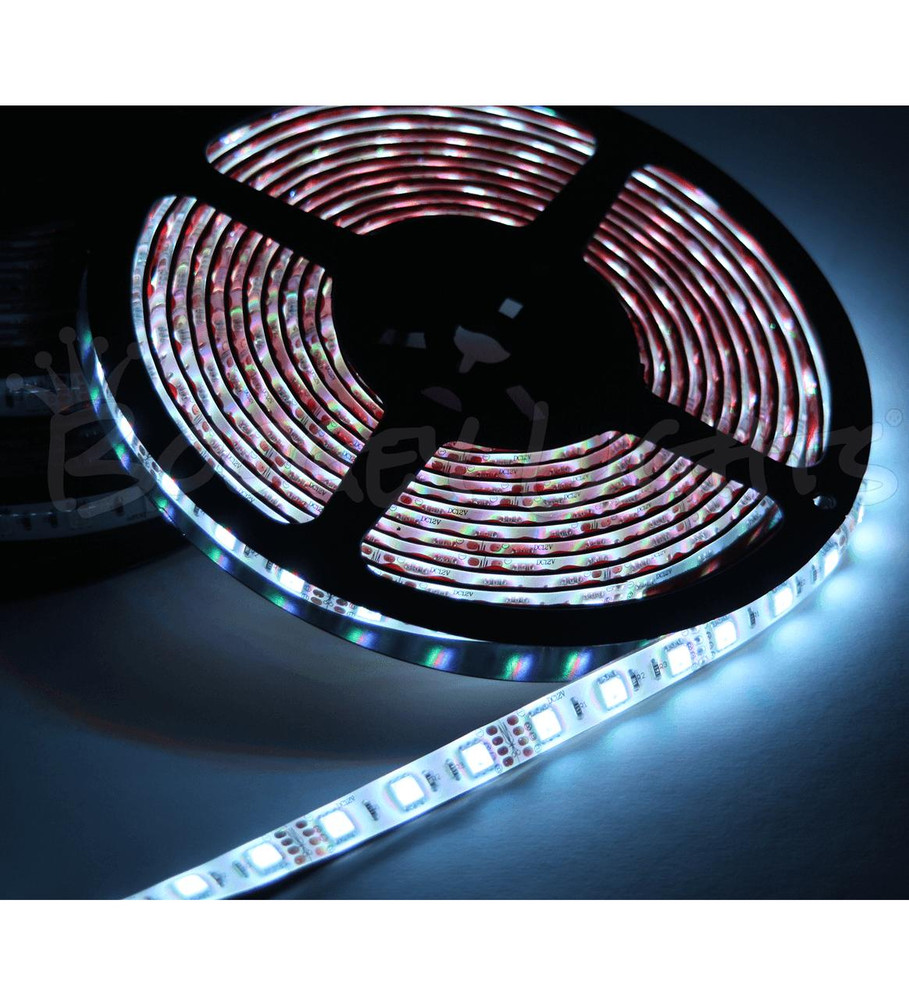

DIY LED STRIPS

Are you a hobbyist who likes to do their own soldering? If so, our DIY LED strips might be just what you're looking for. We offer our hi-intensity low profile LED strips without power leads in lengths ranging from 2" to 197". Just the LED strip with 3M industrial grade VHB tape on the back (3M adhesion promoter strongly suggested, not included). Available in a variety of single colors, RGB, RGBA, RGBW and RGBWW. All types are offered on BLACK PCB with a few offered on the optional WHITE PCB. 5050 high-intensity LEDs, IP65 rated. All versions of these RGB LEDs are common cathode and require a BOOGEY LIGHTS LED controller to operate (not included). This product is typically used by hobbyists who like to do their own soldering for custom projects intended for use on indoor stationary applications. If you're looking for LEDs to attach to a vehicle or to be used in environments that are exposed to the elements we strongly recommend using our SURFACE MOUNTED LOW PROFILE LED STRIPS instead of this product.

This product is just the LED strip in the length and color configuration you select. THERE IS NO POWER LEAD. You will need to do your own soldering. SOLD AS IS. NO WARRANTY.

Important Self-Soldering Warranty Note

This product is intended to be purchased by hobbyists who are using it for indoor applications. If you are buying this product we assume you know what you're doing. Only the most technically capable should be attempting to do their own soldering to attach power leads to the LED strip. If you aren't familiar with flexible Printed Circuit Board layout, how to identify the GROUND solder point on the PCB, how to solder (too much heat could melt the PCB and/or damage the closest LEDs), how to test and trouble shoot your work, how to correctly seal the solder point to avoid water intrusion and in general how LED strip lighting works, we strongly suggest allowing us to do the soldering and heat shrinking for you (select our SURFACE MOUNTED LED STRIPS). We do not warranty this product beyond confirming all LEDs are working properly when leaving our facility. This product does not come with a warranty beyond that point.

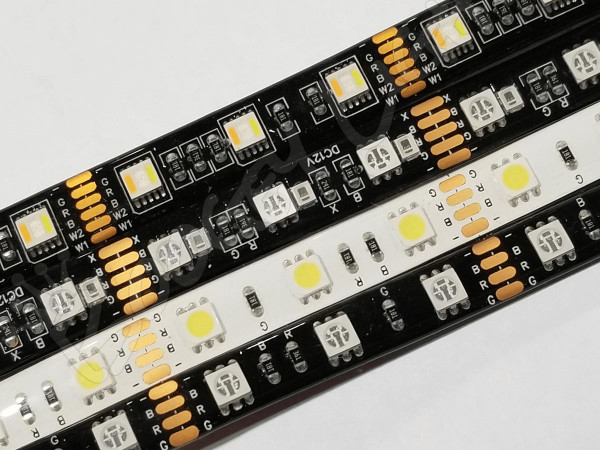

WHAT IS RGBW?

On the RGBW led strip, in addition to RGB, you get one extra diode which is Warm White. That warm white diode has a Kelvin temperature of 2400 which means it has a yellowish look giving it a warmer, softer, candle like look (see photo below). That fourth diode on the RGBW led strip is often wired to simple ON/OFF switch OR zone 2 of our Dual Zone LED controller. See the SPECS tab on this product page for more details on this option.

WHAT IS RGBA?

On the RGBA led strip, in addition to RGB, you get one extra diode which is AMBER. That fourth diode on the RGBA led strip is often wired to a simple ON/OFF switch or zone 2 of our Dual Zone LED controller. See the SPECS tab on this product page for more details on this option.

WHAT IS RGBWW?

On the RGBWW led strip, in addition to RGB, you get two extra diodes: One is Warm White (2400 Kelvin) and one is Natural White (4500 Kelvin), Like the RGBW led strip, you can wire one (or both) of these two diodes to an existing OEM switch or connect them to a dimmer switch(es) or even another LED controller. Some customers will even use our Dual Zone LED controller with RGBWW led strips. Zone one of the controller is wired to the RGB diodes. Zone two of the controller is wired to one or two of the WW diodes. See the SPECS tab on this product page for more details on this option. NOTE: The longest length RGBWW LED strip we currently offer is 72".

IMPORTANT RETURN POLICY NOTE

This product is considered a custom ordered product. With the sole exception of the full roll (197"), we DO NOT accept returns for this product.We will accept returns of a full roll within 30 days of purchase IF the roll is returned in new condition (not yet soldered) and able to be resold as new. Be sure to read our RETURN POLICY for details.

ALL RGB STRIPS ARE COMMON CATHODE LEDS

The RGB diodes in any of our Multi-Color LED Strips (RGB, RGBA, RGBW, RGBWW) are common cathode LEDs. They require a BOOGEY LIGHTS LED CONTROLLER.

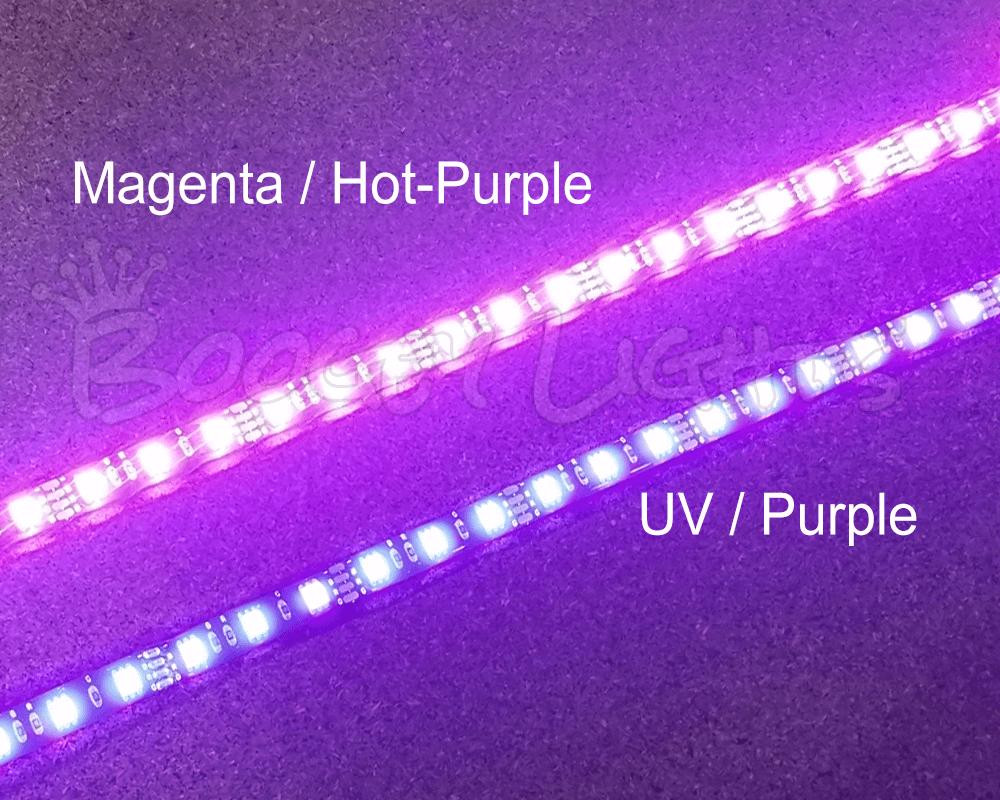

NOTE ON UV/PURPLE SINGLE COLOR LEDS

Return Policy Note: This product is considered a custom ordered product. With the sole exception of the full roll (197"), we DO NOT accept returns for this product.We will accept returns of a full roll within 30 days of purchase IF the roll is returned in new condition (not yet soldered) and able to be resold as new. Be sure to read our RETURN POLICY for details.